Introduction:

The textile manufacturing industry has always been a hub of innovation, and it’s about to witness an even greater transformation with the integration of automation and robotics. This blog explores how advancements in technology are reshaping textile manufacturing processes, from spinning yarn to cutting and sewing fabrics. We will delve into the benefits and challenges of automation and robotics, their impact on production efficiency and quality, and the implications for the workforce. The future of textile manufacturing is being shaped by these transformative technologies, paving the way for a new era of speed, precision, and sustainability.

The Rise of Automation in Textile Manufacturing:

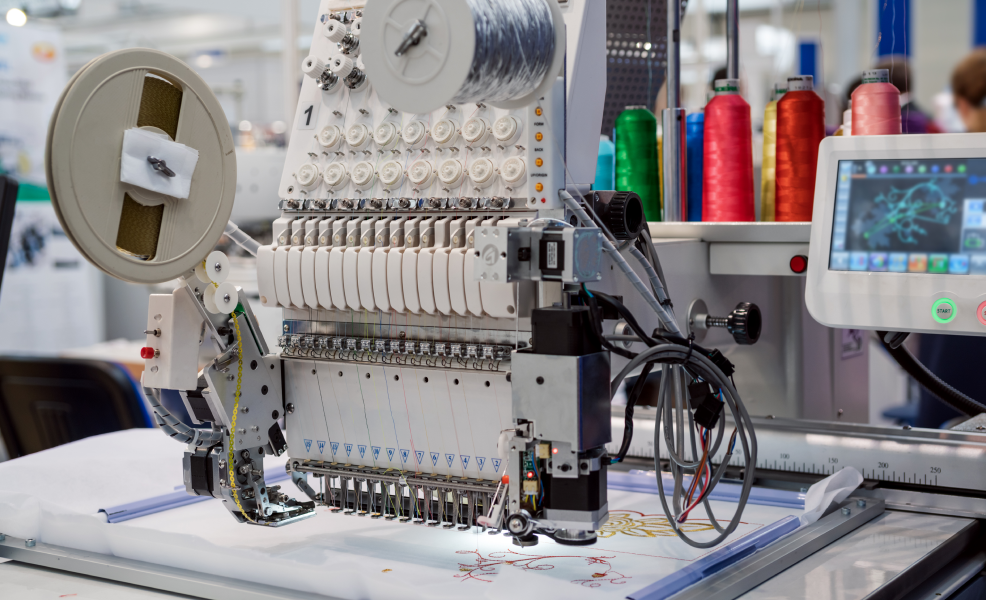

Automation has emerged as a game-changer in the textile manufacturing industry. Advanced machinery, equipped with sensors and artificial intelligence, is replacing labor-intensive tasks, improving production speed, accuracy, and consistency. From automated looms and knitting machines to robotic cutting and folding systems, the adoption of automation streamlines the manufacturing process, reduces human error, and enhances overall productivity.

Robotics in Fabrication and Assembly:

Robotic systems are revolutionizing the fabrication and assembly stages of textile & garments manufacturing. Collaborative robots, known as cobots, work alongside human operators, performing repetitive tasks with precision and speed. They excel in activities such as fabric cutting, stitching, and garment assembly. With their ability to handle complex patterns and variations, robots offer improved efficiency, enhanced quality control, and flexibility in production.

Advantages of Automation and Robotics in Textile Manufacturing:

The integration of automation and robotics in textile manufacturing brings numerous benefits to the industry. Firstly, it significantly reduces production time, enabling faster turnaround and meeting ever-increasing customer demands. Secondly, automation improves product quality through precise measurements, cuts, and stitches, resulting in more consistent and durable textiles. Thirdly, the use of textile robotics minimizes material waste, optimizing resource utilization and reducing environmental impact. Additionally, automation enhances workplace safety by automating hazardous tasks, thus protecting human workers from potential injuries.

Challenges and Considerations:

While the future of textile & apparel manufacturing seems bright with automation and robotics, several challenges need to be addressed. Initial investment costs can be high, requiring careful financial planning and analysis. Furthermore, integrating automation into existing production lines may require reconfiguring layouts and training employees to work alongside robots. Concerns about job displacement also arise, necessitating a shift towards upskilling and reskilling the workforce to adapt to the changing industry landscape.

The Role of Human Workers in the Automated Future:

Contrary to popular belief, the rise of automation and robotics does not render human workers obsolete. Instead, it redefines their roles in the textile manufacturing process. With textile automation taking over repetitive and physically demanding tasks, human workers can focus on higher-value activities such as design, creativity, quality control, and maintenance of robotic systems. The collaboration between humans and machines unlocks new opportunities for innovation and craftsmanship in the industry.

A Sustainable Future with Automation and Robotics:

The integration of automation and robotics in textile manufacturing aligns with the pursuit of sustainability. These technologies enable more efficient resource management, waste reduction, and optimized energy consumption. By minimizing errors and rework, they contribute to overall sustainability goals. Furthermore, the faster production cycles achieved through textile automation and robotics can lead to reduced carbon emissions and a smaller environmental footprint. The future of textile manufacturing envisions a harmonious coexistence of automation, robotics, and sustainability.

Conclusion:

Automation and robotics are ushering in a new era of efficiency, precision, and sustainability in textile manufacturing. With advancements in technology, the industry can embrace these transformative tools to optimize production processes, improve product quality, and minimize environmental impact. While challenges exist, the integration of automation and textile robotics does not eliminate human workers but rather empowers them to focus on higher-value tasks. The future of textile manufacturing lies in harnessing the collaborative potential of human skills and robotic capabilities, paving the way for a dynamic and sustainable industry.